- For powder coated , we have normal powder coated and outdoor powder coated . Outdoor powder coated finish can be gold, copper , chrome , black , and coffee gold color . They are very luxury color just as electric plating finish , but can be suitable for indoor and outdoor use .

- Electrostatic spraying is based on the principle of electrostatic attraction, that is, the grounded object is used as the positive electrode, and the oil atomizer (ie spray cup or spray plate) is connected to high-voltage electricity as the negative electrode.

The steel strip to be oiled passes through the upper and lower fuel injection beams. The fuel injection beams are made of special aluminum alloy and fixed on an adjustable insulating support arm. The gap on the fuel injection beam can be evenly adjusted to 0.2mm, and an oil groove is opened inside it, the oil inlet pipe is connected in the middle, and the two oil return pipes are connected to both ends. The upper and lower fuel injection beams are separated from the strip steel by a certain distance, and the fuel injection beams are designed so that the oil flows to the fuel injection port under zero pressure. When the fuel injection beam is energized, a high-voltage electrostatic field is generated between the fuel injection beam and the grounded steel strip, and a corona discharge is generated at the negative electrode to make the sprayed oil mist negatively charged. Charged particles are affected by the electrostatic field and are efficiently and uniformly adsorbed to the passing steel strip along the direction of the power line, presenting a unique “environmental effect”. Electrostatic spraying can also use positive corona discharge, but the critical voltage (initial voltage) of negative corona discharge is lower than that of positive corona discharge, which is more stable, safe and not easy to produce fire. - Features

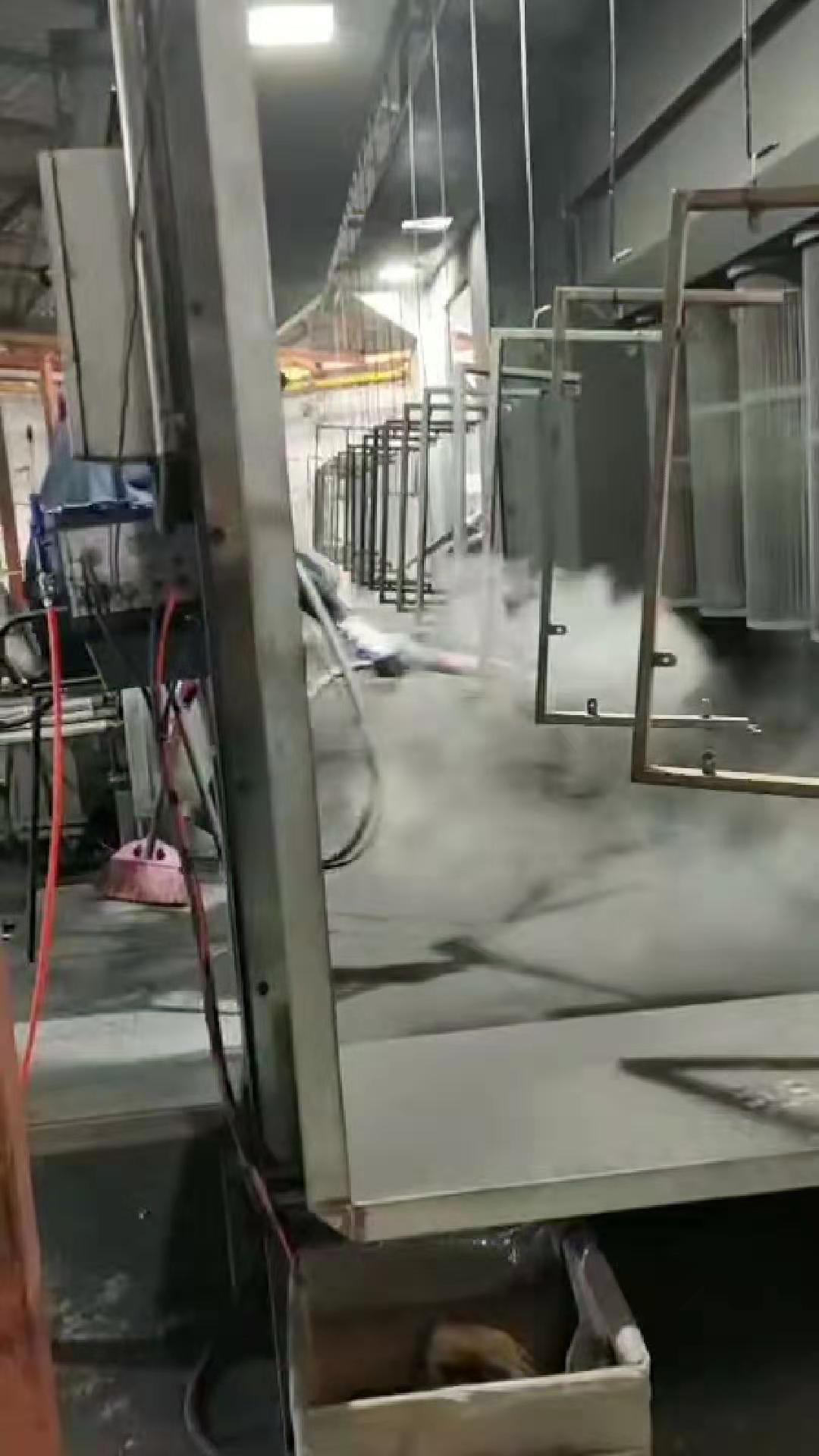

(1) The construction environment and working conditions are good. The stationary electrostatic spraying equipment that is more widely used is usually matched with a suspended conveyor to form a continuous coating production line. In this case, the operator’s work is limited to the preparation, loading, and unloading of the painted workpiece, as well as the regulation and care of the equipment. Therefore, the opportunity for direct contact with the paint and the intensity of physical labor are greatly reduced. Moreover, when spraying in a high-voltage electrostatic field, the spread of paint mist is far less than that of air pressure spraying or airless spraying, so that the pollution of the coating environment is significantly improved.

(2) High paint utilization rate. When spraying in a high-voltage electrostatic field, the negatively charged paint particles are painted on the surface of the workpiece along the direction of the power line. Therefore, there is basically no paint jet rebound and paint mist scattering phenomenon, the paint mist loss is very small, and the paint utilization rate can reach 85% to more than 90%.

(3) Good finishing quality. When electrostatic spraying is carried out in strict compliance with the correct operating procedures, due to the effect of the high-voltage electrostatic field, the dispersion of paint particles is high, and the distribution of the particles in the jet is relatively uniform. Therefore, the coating formed on the surface of the painted workpiece is also flat and uniform. The gloss and adhesion of the film are both high. - (4) High finishing efficiency. Production practice shows that in the electrostatic spraying continuous flow production line, the running speed of the conveyor belt can reach 24m/min, far exceeding other spraying lines. For those wooden parts, such as tables, chairs, frames, etc., that are impossible to use with the frame structure of curtain coating or roller coating, the comprehensive economic benefits of electrostatic spraying are particularly obvious.

The main disadvantage of the electrostatic spraying method is the high fire hazard, especially when sparks are caused by improper spraying distance or incorrect operation, it is easy to cause a fire. Therefore, there must be reliable fire-proof and explosion-proof facilities, and strict compliance with safety operating regulations. In addition, for surfaces with complex shapes or deep contours, it is difficult to obtain uniform coatings by electrostatic spraying.

Leave A Comment